Döktaş uses up-to-date project management tools to deliver high quality parts on time. “Project Manager” and “Project Team” that is created at the beginning of the project targets “First Time True” by effective use of resources and lessons learned.

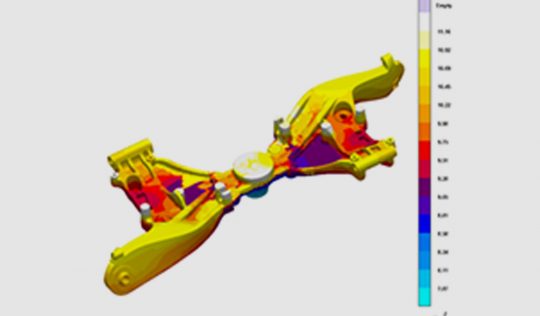

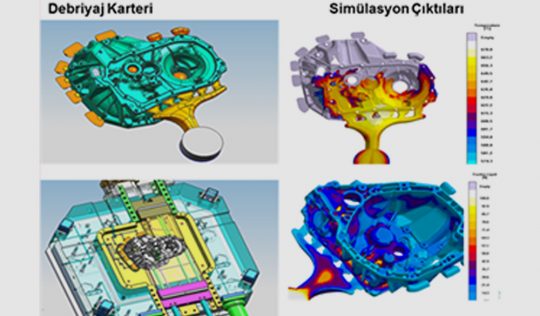

Product and Process Design

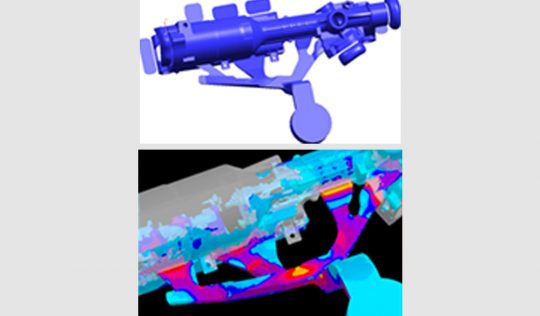

Aluminium Business Unit Engineering Team who are oriented to be a “Solution Partner” to our customers, uses CAD and Casting Simulation softwares to improve part design to minimise production risk for both Casting and Machining operations. Optimum solution is applied to problems after design review meetings and co-engineering studies between Döktaş and Customer engineering teams.

Together with part design improvements, Alu B.U. Team also provides solution/improvement proposals to Customers for Casting process selection, Material selection, Heat Treatment options, Machining Referances and dimensional & geometric tolerances.

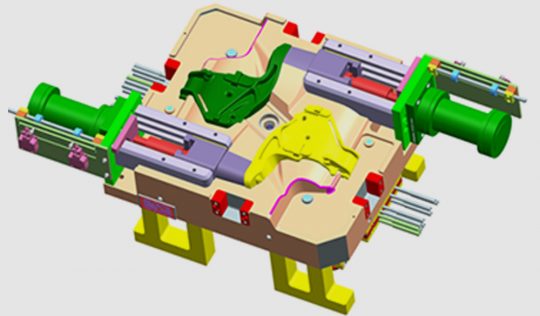

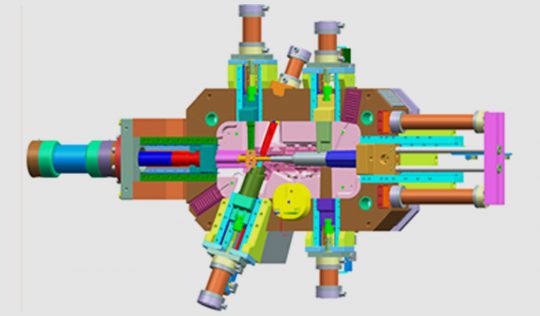

Tool Engineering

Almost all casting tools are designed by Alu BU Engineering Team. From design to manufacturing all past experiences are use on new project tools by design review meeting not only within department but also together with Production&Quality teams and Tool Manufacturer.

When the casting tool is ready for trial, hot trials are done at Döktaş Manisa Aluminum Foundry. Corrective and improvement actions decided and applied after trial according to trial report and measurement results.

Process Engineering

After all production tools such as casting tool, machining fixture, gauges etc. are completed, trial runs and PPAP process are managed by Engineering team. Project is handed on to Production Department after SOP when Ramp-Up is completed with desired results.